FL - 100 : Two Wire Turbine Flow Meter with LCD display

Working Principle

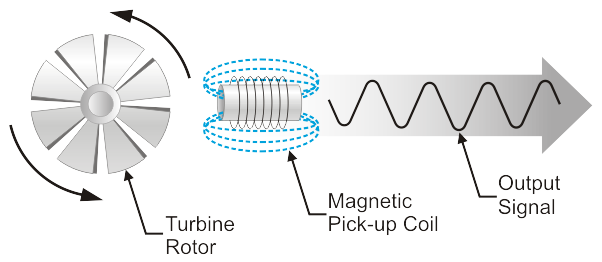

The Turbine Flow meter is used for the measurement of liquid flow rate. It works on the principle of Turbine. A turbine flow meter is constructed with rotor and blades that use the mechanical energy of the fluid to rotate the rotor in the flow stream. Blades on the rotor are angled to transform energy from the flow stream into rotational energy. The rotor shaft spins on bearings - When the fluid moves faster, the rotor spins proportionally faster.

The diameter of the rotar is slightly less than the inside diameter of the pipe, and its speed of rotation is proportional to the volumetric flow rate. The magnetic pick-up coil consists of a permanent magnet with coil windings which is mounted in close proximity to the rotor. As each rotor blade passes the magnetic pick-up coil, it generates a voltage pulse which is a measure of the flow rate. The total number of pulses gives a measure of the total flow.

Product Description

Electronet series FL-100 are Two Wire Turbine Flow Transmitters specially used for various industrial applications. The flowing media engages a vaned rotor causing it to rotate at an angular velocity proportional to flow rate. The pick-up coil senses the spinning motion of the rotor inside the pipe & converts it into a pulsating electrical signal. Summation of the pulsating electrical signal is directly related to the total flow.

The frequency is linearly proportional to flow rate which is converted to electrical signal 4 - 20 mA. Turbine flow meters are preferred for clean, filtered, low viscosity fluids. The typical accuracy and repeatability of turbine flow meters are Plus/Minus 0.5% and Plus/Minus 0.1%, respectively. However, it is possible to achieve accuracy of Plus/Minus 0.25% and repeatability of Plus/Minus 0.05%.

Turbine flow meters are inherently sensitive to Reynolds number. They will not be linear at Reynolds numbers nearing or in the laminar region. Therefore, they should be carefully used in the case of fluids with a broad temperature and viscosity range such as some oils. It is not a problem at constant conditions, but is often hard to achieve practically.